Get In Touch

- [email protected]

- +86 173 180 77353

-

Yantian Port, Yantian District, Shenzhen, Guangdong Province

Postal code: 518085

Among the innovative solutions reshaping the landscape, precision manufacturing in paper tube packaging is emerging as a game-changer for electronics. This article explores how precision manufacturing is revolutionizing paper tube packaging and what the future holds for this eco-friendly and efficient solution.

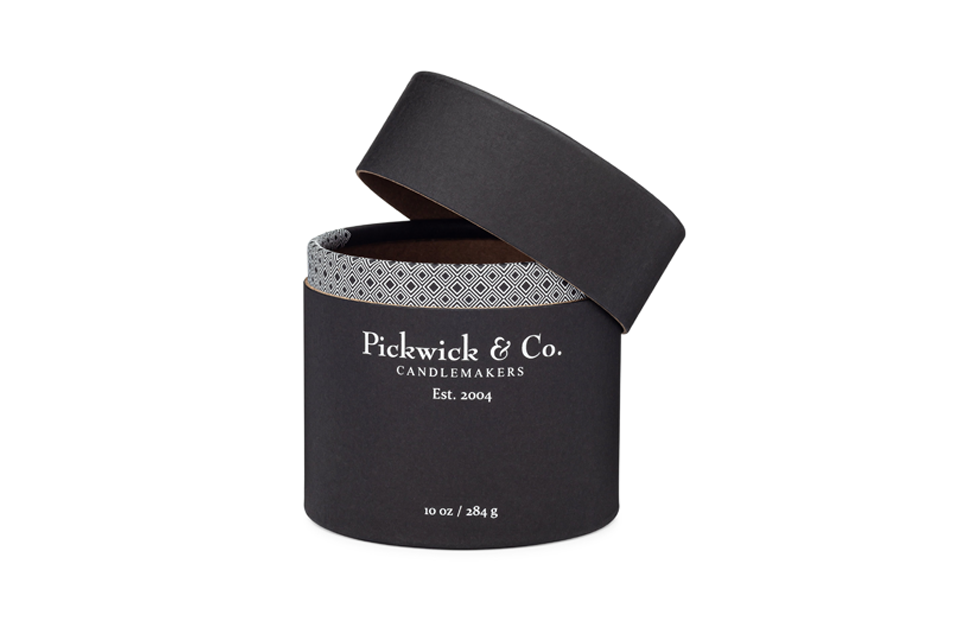

Paper tube packaging has long been valued for its durability and versatility. Traditionally used for products like cosmetics and food items, paper tubes are now gaining traction in the electronics sector. This shift is fueled by increasing consumer demand for sustainable packaging solutions and the need for protective, high-quality packaging that can withstand the rigors of modern supply chains.

Precision manufacturing refers to the use of advanced technologies and techniques to create highly accurate and consistent products. In the context of paper tube packaging, this means utilizing state-of-the-art machinery and processes to produce tubes with exact dimensions, smooth surfaces, and reliable performance.

Enhanced Protection and Durability

Precision manufacturing ensures that paper tubes are crafted to precise specifications, providing superior protection for electronic components. This is crucial for sensitive electronics that require a stable and secure packaging environment to prevent damage during transit and storage.

Customizable Designs

With precision manufacturing, paper tubes can be tailored to meet specific requirements. This customization extends to dimensions, printing, and finishes, allowing electronics manufacturers to create packaging that not only protects their products but also enhances their brand image. From sleek, minimalist designs to vibrant, eye-catching graphics, the possibilities are endless.

Improved Sustainability

As sustainability becomes increasingly important, precision manufacturing in paper tube packaging offers a greener alternative to traditional plastic packaging. Paper tubes are made from renewable resources and are often recyclable, aligning with the growing push towards eco-friendly practices in the electronics industry.

Cost-Effective Solutions

While precision manufacturing involves advanced technologies, it can also lead to cost savings in the long run. High-quality paper tubes reduce the risk of damage and returns, and their customizable nature means that manufacturers can optimize their packaging solutions to meet specific needs without excessive waste.

The future of paper tube packaging for electronics looks promising, driven by continued advancements in precision manufacturing and growing environmental consciousness. As technology evolves, we can expect to see even more innovative applications and improvements in paper tube design and production.

Integration of Smart Technologies

Future developments may see the integration of smart technologies into paper tube packaging. For example, incorporating QR codes or NFC tags could provide consumers with detailed product information and enhance the overall user experience.

Enhanced Functionalities

Precision manufacturing could lead to the development of multifunctional paper tubes that offer additional features, such as built-in protection against electromagnetic interference or specialized compartments for different electronic components.

Global Adoption

As the benefits of paper tube packaging become more widely recognized, we may see broader adoption across the global electronics market. This shift could drive further innovation and standardization, making paper tube packaging a mainstream choice for electronics manufacturers worldwide.

Precision manufacturing is paving the way for a new era in paper tube packaging, particularly in the electronics sector. By combining advanced technologies with sustainable materials, paper tube packaging offers enhanced protection, customizable designs, and eco-friendly benefits. As we look to the future, it is clear that precision manufacturing will continue to play a pivotal role in shaping the evolution of packaging solutions, offering exciting possibilities for both manufacturers and consumers alike.

Paper tube packaging is an eco-friendly and recyclable packaging option that is suitable for a variety of industries and products. Here’s a detailed overview of its common applications:

In the highly competitive packaging industry, quality assurance (QA) is not just a process—it’s a commitment to excellence that separates premium products from the rest.

In the ever-evolving world of packaging, the need for sustainable, functional, and aesthetically pleasing solutions has never been more critical.

The packaging industry is undergoing a significant transformation as brands and consumers alike seek more sustainable alternatives to traditional packaging materials.

Paper tube packaging is an eco-friendly and recyclable packaging option that is suitable for a variety of industries and products. Here’s a detailed overview of its common applications:

Paper tubes are increasingly recognized as a sustainable alternative to traditional plastic packaging.

In a world increasingly aware of environmental issues and the urgent need for sustainable practices, product packaging has come under scrutiny.

In today’s competitive market, packaging plays a crucial role in attracting customers and enhancing brand identity.

Didn’t find what you want?Ask our manager for help!